Our Process

What Soulé Organics want to present apart from organic fruits and vegetables there are organic spices available which is important for the health and not harsh on our Mother Nature.

ORAGNIC PRODUCTS FOR THE PEOPLE

ABOUT SOULE ORGANIC

Spices have been closely associated with cultural traditions, rituals, preservation, medicines and mainly cuisines for human life since centuries.

Soulé Organic Spices as a brand is trying to bring the finest blend so that the rich culinary tradition of various cultures remain intact.

Know us better

Soulé Organic in numbers

0

+

Organic Herbs & Spices

0

+

Quality Certifications

0

+

Countries Supplied

0

+

Engagement With Farmers

SOULE ORGANIC PRODUCTS

We ensure that our spices and herbs are procured from reliable and certified vendors of the markets in compliance with international quality standards. All our products are tested from procurement to processing and packaging to ensure that they are absolutely pure and free from any contamination.

Procurement

We source our spices and herbs directly from the premium growing regions of the world. Our global procurement team establishes relationships with local collectors & farmers to ensure a steady supply of high-grade product while maintaining ethical trade practices.

Lab Testing

Our Lab Testing process is the most important step that complements each stage of our total supply-chain.

A rigid and robust sampling & testing program, at every point ensures our commitment to the highest quality and product consistency. Soulé Organic program consists of a fully-integrated QC lab, complete with testing capabilities on physical, chemical, micro/macro-sanitary & microbiology parameters as well as Plant Environmental Sanitation and Inspection standards.

CO2 Fumigation

When carbon dioxide is applied, spices are placed in sealed chamber and exposed to the gas for a specific time until they are removed from the chamber by an organic inspector.

Adding carbon dioxide inside the chamber replaces the oxygen to achieve a low oxygen condition, which is toxic to the insects when maintained over a given time. This leaves no residue behind spices, which can affect their quality during transit.

Steam Sterilization

The main advantage is, the High temperature, Indirect Contact Pre-heating, which uses a minimum quantity of steam directly on the product. The steam is passed through a series of critical valves that purify the steam before it comes into contact with the product. The process ensures retention of Volatile Oil and use of steam eliminates the uses of Drying post sterilization.

The cooling, post sterilization takes place in a High Care area before being packed in a Class 100,000 Clean Room.

Cold Grinding

This technology uses cold water supply to control the grinding chamber temperature through a complete stainless steel pipes WEB inside the grinding chamber hence the result of which is reduction in loss of volatile essential oils in the spices and higher production rate. This grinding technology improves the aroma by minimizing the loss of essential oils (approx. 3% loss) which is approx 43% in conventional processing. Spices are ground to a thickness of 50 microns.

People Say About Soulé Organic

Absolutely love your spices !! They are so great !! They have such great fresh flavor and the smell when you open them is amazing. I will be a repeat customer many times over.

James Larson, Sydney

We have been using your spice for quite sometime now. And couldn’t find your spice like yours anywhere! We also get it sent as gifts as all our friends know we love it so much.

Matt Davids, Perth

I am so happy with all the products that I have obtained from Soulé

Organic. My last order was Steak Seasoning. But I have been very happy with the length of time to get the spices to me. Thank you for saving me money also and the spices are superior.

Neil Patricks, Wellington

I'm in love with my spices from Soulé Organic. I am looking forward to making warm turmeric milk tonight with your beautifully colored turmeric, and it smells so wonderful! Thank you for all your help!

Joseph Parsons, Auckland

Thanks for the great descriptions of all your spices. Now I know what’s what lol.

Jessica Marcel, Christchurch

Previous

Next

Certified Organic Source

High Nutrition

Preserves Natural Oils

No Added GMO

Preserves the Environment

Vegan

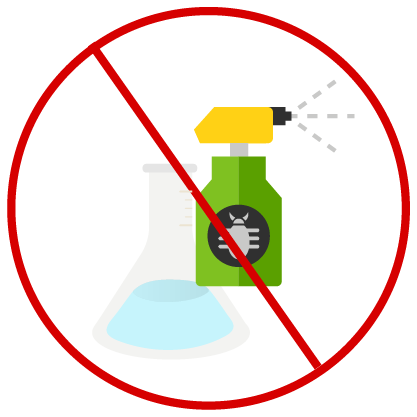

No Chemical Pesticides

Previous

Next